The fashion industry’s waste problem has reached alarming proportions, calling for innovative solutions that reshape the entire fashion ecosystem. In this pursuit, Unspun, a pioneering startup renowned for its custom-fit jeans, has made a groundbreaking leap with the introduction of 3D weaving technology. Backed by a significant $14 million funding boost, Unspun aims to revolutionize production methods and combat waste on a global scale. Let’s delve into Unspun’s game-changing approach and the potential it holds for transforming the fashion industry.

The Fashion Waste Epidemic: A Call for Change

The fashion industry has been a significant contributor to plastic microfibers entering our oceans, and the problem of waste has been receiving increasing attention lately. Every year, millions of tonnes of clothes are produced, worn, and thrown away, and every second, a rubbish truckload of clothes is burnt or buried in a landfill. To solve the problem of waste, the industry must reinvent itself. There lies the significance of a revolutionary company like Unspun.

Reducing Waste through Just-in-Time Production

Unspun was launched in 2015 with a mission to reduce waste at the consumer end by leveraging 3D scanning to fit jeans precisely for individual buyers and manufacture them on demand. The company’s new 3D weaving initiative targets waste at the manufacturing end. By enabling localized production in small batches, the technology helps brands react swiftly to demand and even make products on demand, eliminating the need for excess inventory. With their precise fits and relatively high prices, Unspun jeans are meant to be worn for a long time rather than discarded quickly. But waste remains an enormous problem across fashion, with millions of tons of clothing produced and thrown away each year.

The company’s new 3D weaving initiative targets waste at the manufacturing end. By enabling localized production in small batches, the technology helps brands react swiftly to demand and even make products on demand, eliminating the need for excess inventory. Unspun touts this ‘short and agile supply chain’ as significantly reducing costs, emissions, and waste.

3D Weaving: A Microfactory Revolution

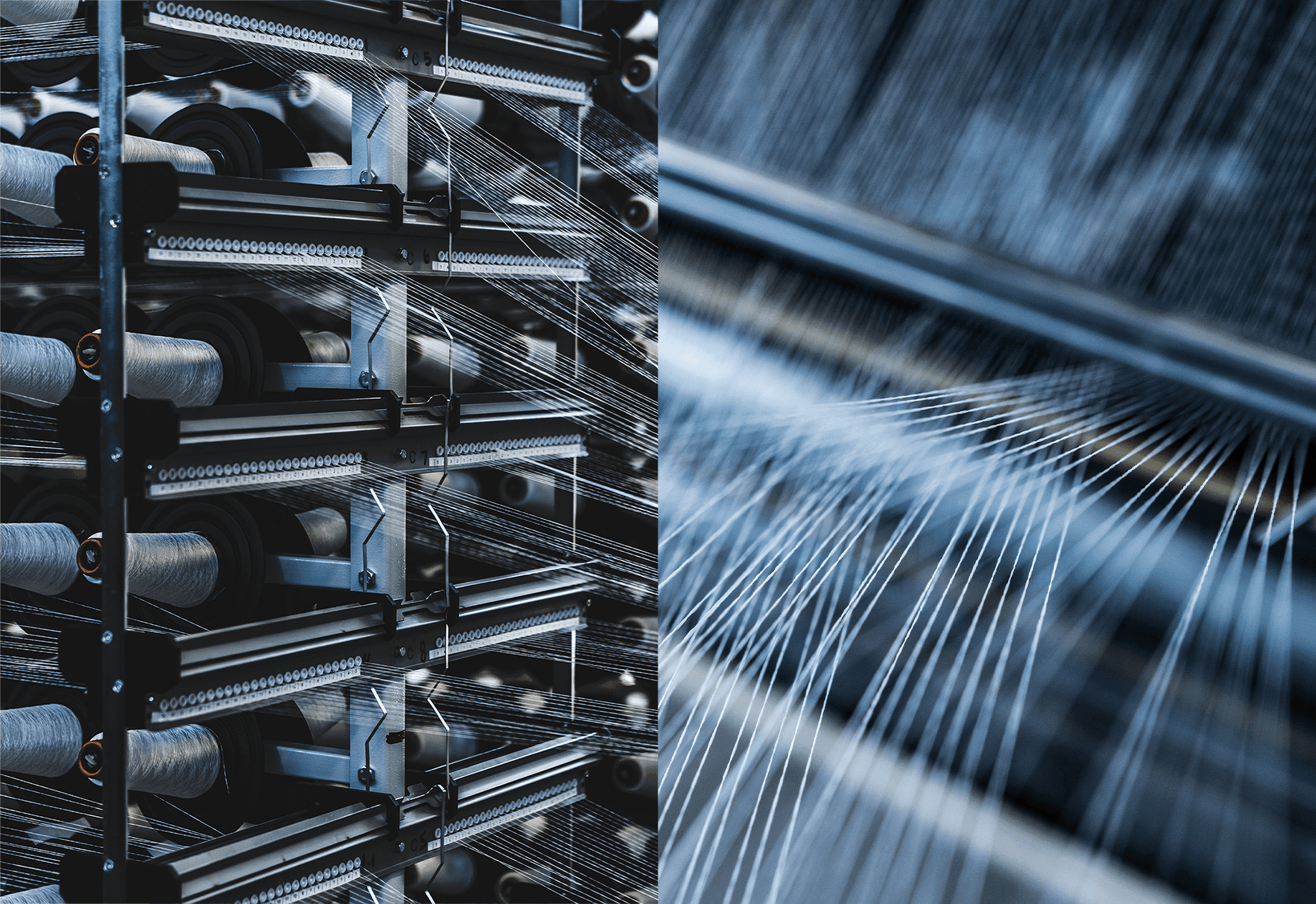

Unspun’s new 3D weaving machine, Vega, can weave a pair of pants to order in just 10 minutes, from scratch. The robotics-enabled device is inspired by additive manufacturing principles and is fed directly with yarn, with no fabric inputs involved. Just a few minutes’ worth of finishing steps are needed to complete the process.

With Vega, Unspun aims to set up micro-factories around the world to provide brands with a faster, more localized, and more agile model of production. Brands can produce smaller batches and quickly react to market demands or even produce products on demand, eliminating the need for inventory altogether. This approach not only reduces transport costs and emissions but also creates a short and agile supply chain that requires little or no inventory.

The Big Picture

Unspun’s sustainable and technologically innovative solution comes at a time when the fashion industry is under scrutiny for its outsize environmental footprint. By reinventing how clothes are made and distributed, Unspun aims to push fashion toward a zero-waste circular model. Their vision of localized micro-factories could transform manufacturing as we know it.